Heavy industry is responsible for 30% of global greenhouse gases emissions. Currently, two-thirds of industrial emissions come directly from material processes. New energy, management and technology solutions are needed to decarbonise raw materials extraction, production processes and operating systems in every sector.

Now is the time to connect and establish new partnerships between companies, innovators and other stakeholders to reduce industry’s climate impacts. The overall aim is to move from inefficient, polluting linear production systems to closed loop methods underpinning the circular, low-carbon economy.

Sweden’s steel sector is a good example of the positive actions that can be taken. Its steel producers aim to have the first commercial scale zero-emissions steel plant in operation by the early 2030s. This is important. Steel accounts for 7% of total CO2 emissions. Rapid urbanisation, new buildings and infrastructure construction and adaptation to inevitable climate impacts will all increase demand for steel in the coming 30 years. Decarbonisation is an essential strategic objective.

The steel industry’s HYBRIT project in the Arctic is an excellent example of how steel production can become fossil free, by both using new technology and bringing together a wide variety of stakeholders in a shared purpose.

In 2016, three giant companies came together to develop fossil-free steel: LKAB (Europe’s largest iron ore producer); SSAB (the global leader in high-strength steel production; and Vattenfall (one of Europe’s largest electricity producers). Their partnership has led to a new manufacturing process: HYBRIT, or Hydrogen Breakthrough Ironmaking Technology.HYBRIT aims to replace carbon-heavy coal with clean hydrogen to become the world’s first fossil-free steel-making technology.

Government backing is also critical for success. Sweden aims to become a net-zero carbon economy by 2045, and actively supports low-zero carbon innovation. The country recognises the economic advantage of leading the low carbon transition. Helping the economically crucial steel sector ‘go green’ is central to succeeding.

Sweden is in a unique position to clean up steel production. The country has an abundance of fossil-free hydro power, and Europe’s highest quality iron ore. Its steel sector is already highly specialised. And, most importantly, the country is known for its ‘systems-literate’ approach to solving problems cross-sectoral problems.

One example of the prevalence of systems thinking in Swedish cities is how the energy sector joined forces with water and waste management systems to produce district heating, successfully reducing emissions and climate impact. Following this approach, HYBRIT brings mining, steel-making and energy together to jointly create a new production system, which benefits the companies, the country and climate.

The Market

The global steel industry has been slow to transition to low-emissions operations. For example: the EU has controversially allowed steel companies to continue to operate blast furnaces that burn coal and coke until 2026, significantly delaying progress. EU carbon allowances should have been used to help transition the steel sector towards net zero. Many analysts point out that the extended period of free allowances has delayed the radical changes the steel industry needs to implement to both remain competitive and meet the EU target of carbon-neutrality by 2050.

Initially, a 2016/17 HYBRIT feasibility study showed that fossil-free steel could be 20-30% more expensive, given the relative costs of electricity, coal and CO2 emissions. Today, the declining prices of fossil-free electricity, combined with increasing costs of CO emissions under the European Union Emissions Trading System (ETS), now show that HYBRIT can compete with traditional ‘dirty’ production methods.

The Technology

Gas flaring and blast furnaces versus HYBRIT

Out of 30 active blast furnaces in the EU, only three in Eastern Europe have not installed technology to minimise flaring and recycle CO2 gases to heat circuits or generate electricity. But these procedures do not reduce CO2 emissions in a significant way and will not help the steel industry to comply with EU CO2 carbon reduction targets.

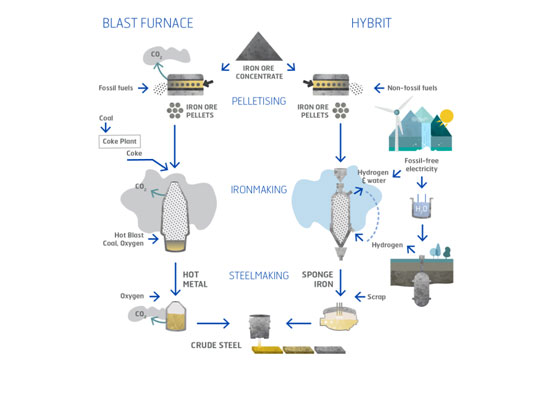

The HYBRIT technology promises a great deal for the sector, because it shows how to replace coal, coke and other fossil fuel with renewable electricity and hydrogen (whose by-product is water). The HYBRIT programme will be almost completely fossil free because the hydrogen is produced from the electrolysis of water using renewable electricity sources.

HYBRIT’s entire industrial process – from ore mining to smelted iron to pellet production to finished steel products – is based on adopting Sweden’s joined-up approach to tackle related industrial challenges.

The strength of their feasibility studies persuaded LKAB, SSAB and Vattenfall to construct of the world’s first pilot plant for fossil-free steel production at the SSAB site in Luleå, Sweden.The total cost for the pilot plant is estimated at SEK 1.4 billion, split between the Swedish Energy Agency and the three companies.

Other options

The steel industry is testing CCS (Carbon Capture and Storage) as an alternative method of cutting CO2 emissions from blast furnaces. However, CCS has downsides.

Carbon gases can leak from the transportation pipelines to the underground storage reservoirs; as well as from the reservoirs themselves, even in geologically stable rock formations.

Steel plants fitted with CCS technology generally require some 15-25% more energy than conventional plants. This additional energy use can increase emissions indirectly, for example as caused by the extraction and transportation of this additional fuel.

CCS can also cause other types of air pollution. Particulate matter and Nitrogen Oxide are both predicted to increase due to the additional fuel consumption. Ammonia is expected to increase by more than three times current levels from energy plants, due to the degradation of the solvents in the process of capturing Carbon. Ammonia releases can lead to acidification and eutrophication of rivers and lakes.

But the most negative impact of CCS is that it encourages the continued use of fossil fuels..

The Arctic

The three partners in HYBRIT operate in Luleå, a town with 78,000 inhabitants, on the edge of the Baltic sea in the Swedish Arctic region. In Luleå, the mining and steel industry have held a strong position since the 1960s and have dominated employment and regional economic growth.

Last year, Facebook announced its intention to open a third building in Luleå as a part of its European Data Centre investments. The city has abundant hydro power, and the Arctic region will house Europe’s largest battery factory presently under construction.

According to Martin Pei, the CEO of the HYBRIT project: “The main reason why we are here in the Arctic is that we have a skilled and innovative steel-making industry. We also have the only major iron ore mining making in Europe located in this region. And then there is the abundance of fossil-free electricity (Hydropower). I believe these are the reasons that made Facebook established its European datacenter in Luleå.”

To fully succeed, the HYBRIT programme does require significant additional contributions from the Swedish government, the EU and from research institutions and universities. It must have good access to fossil-free electricity, improved infrastructure and rapid expansion of high-voltage networks. Government and EU funding will be needed to scale up the pilot plant to a commercial-scale demonstration plant. Institutional and university expertise is required to identify potential bottlenecks or problems of implementation across all stages of the HYBRIT production process.

To this end, the Luleå University of Technology are partnering with other technology universities to carry out essential preparatory research in areas such as:how to utilize the oxygen produced as a by-product, in the pelletising process; how to use bio-coal to introduce the carbon needed for smelting the iron; and, how to optimize the slag used in the smelting operation to maximise efficiency.

According to Birgitta Bergvall-Kåreborn, Vice Chancellor of Luleå University of Technology, sustainability and climate change priorities are central to the role the University plays. As she says: “The development in the Arctic is an opportunity to change and renew our business structure, sustainable development and attractive living conditions need to be in focus. This requires courageous leadership, innovation, system thinking and endurance, all of which we find in the HYBRIT project. In light of increasingly stringent climate targets, and the rapid reduction in the cost of producing renewable electricity, the option of electrification and the use of hydrogen for making iron and steel has gained increased international attention. HYBRIT can lead the way forward as they develop an entire fossil-free value chain for primary steel production.”

HYBRIT – status and next steps

The HYBRIT pilot plant should be fully operational by mid-2020, and will be a major research facility until 2024. The next stage of the project is to build and start operating a demonstration plant by 2025, three years ahead of the original schedule. The end goal is to be selling ‘fossil free steel’ to meet market demand, and carbon reduction targets by 2035.

This summer the HYBRIT partners also started to build a pilot plant in Malmberget (Arctic Region) to test the production of fossil-free pellets. In parallel, trials will be conducted in an experimental facility in Luleå for CO2-free plasma and fuels not yet commercialised. Another new pilot project will start in Luleå soon, in order to support storage of hydrogen – an important complement to the HYBRIT plant.

The steel industry is capital-intensive and demands re-investment approximately every forty years. If the steel sector is to successfully make the transition to net-zero carbon, there is a need for long-term, systems-wide thinking and applications, and a policy mix that stimulates both the development of and demand for these exciting new technologies and production methods – all of which are essential if the world is to successfully combat climate change while meeting short-term economic and social needs”.

Sweden’s support for HYBRIT demonstrates the power of public risk-taking in mission-oriented innovation for a low-carbon economy, and the government’s commitment to climate leadership through long-term strategy and policy-making.

The HYBRIT project shows how an industrial sector can catalyse positive change by identifying the critical economic and social drivers for substantially cutting carbon emissions, including establishing public, private and social sector partnerships, deploying innovative technology and bringing together multiple stakeholders united in achieving shared sustainability and climate response goals.